- Rapid Vacuum Investment Casting

- Traditional Investment Casting

- Quick Cast and Cast Form Techniques

- Ceramic Mould Casting

TPT offers various technologies for prototyping and short run production of castings.

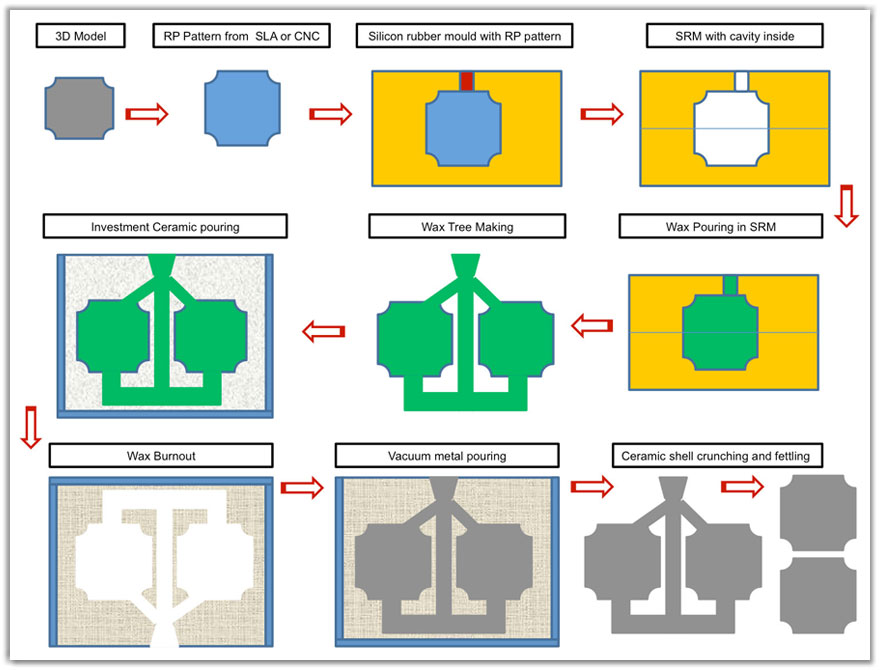

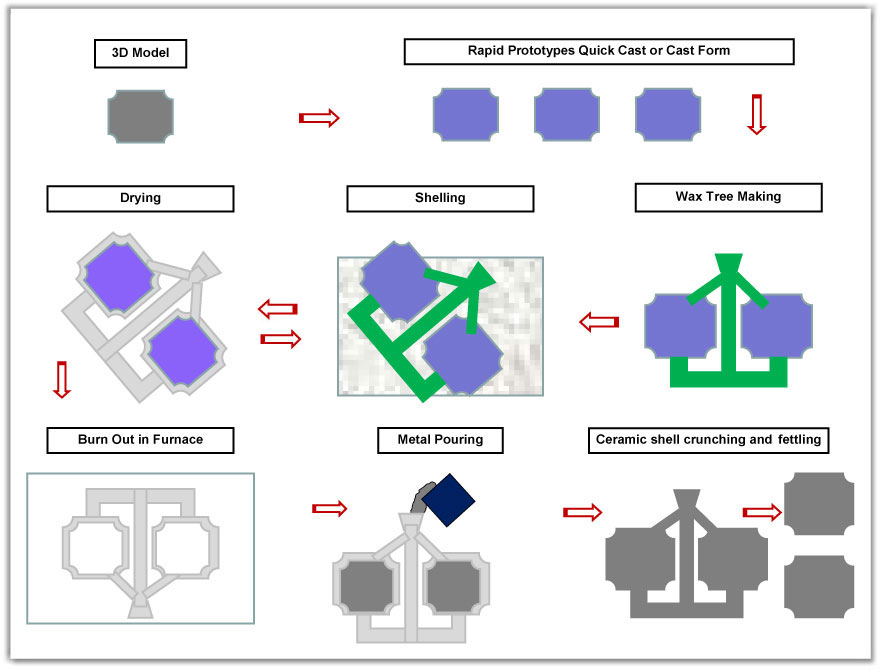

Rapid Vacuum Investment Casting

Rapid vacuum investment casting is a combination of Rapid prototyping and Vacuum casting technologies. Master patterns are made using rapid prototyping techniques followed by investment casting process.

Steps involved in Rapid Vacuum Investment Castings

| 3D CAD model is the Input for our process .This needs to be provided by the customer in STL, IGES or STEP format. | |

| Step 1: | Producing Rapid Prototype Master using SLA or CNC machining. |

| Step 2: | Preparation of Silicon Rubber Mould (SRM) using the RP Master pattern in Vacuum |

| Step 3: | Produce wax pattern (replica of the master pattern) in the SRM. |

| Step 4: | Construction of wax pattern tree by adding sprue, runners and gates. The wax tree is placed in a casting flask |

| Step 5: | Mixing of ceramic investment slurry and pouring under vacuum in to the casting flask . Now the wax tree is completely encapsulated in the investment slurry . |

| Step 6: | The flask is placed in furnace for drying of ceramic and melt out of wax. |

| Step 7: | The flask with the ceramic cavity is placed in the casting machine. |

| Step 8: | Required amount of metal alloy is melted in the induction furnace. Pouring is done under vacuum and over pressure. |

| Step 9: | Flask is removed . The ceramic mould is broken. The metal tree will be fettled and cleaned to get the final castings |

| Step 10: | Heat treatment |

| Step 11: | Machining |

|

|

| Typical Alloys Casted: LM25/A356, A357, LM4, ZAMAK | |

| Contact Us for detailed information on our process. | |

Advantages

- Vacuum reduces porosity & inclusion

- Cost effective

- Precise dimensional control

- Superior surface finish

- Intricate shapes can be cast

- Variety of aluminium and zinc alloys can be cast

- Reduce Material wastage

- Reduce machining required

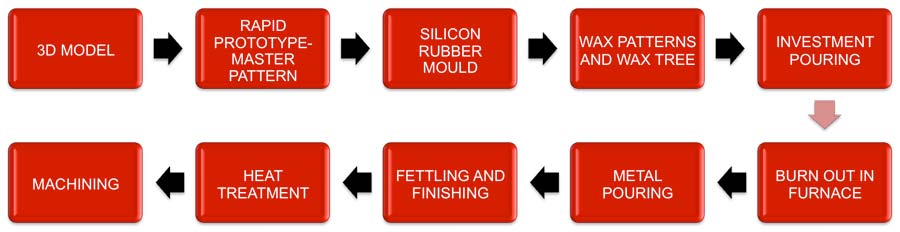

Traditional Investment Casting

Steps involved in Traditional Investment Castings

| Step 1: | Cad data and 2D drawing from Customer |

| Step 2: | Aluminum Die Making for Wax Patterns |

| Step 3: | Wax Pattern Production from Injection Press |

| Step 4: | Construction of wax pattern tree by adding sprue, runners and gate |

| Step 5: | Ceramic Shelling process to form ceramic shell over wax patterns |

| Step 6: | De waxing in Autoclave and ceramic shell burn out |

| Step 7: | Metal Pouring under Vacuum or Open Pouring |

| Step 8: | Ceramic shell breaking , fettling and finishing |

| Step 9: | Heat treatment and sand blasting |

Advantages

- Ideal for Small Batch Production

- Good for precise components

- Good Dimensional Stability

- Die Cost is less compared to PDC

- Variety of Alloys can be cast

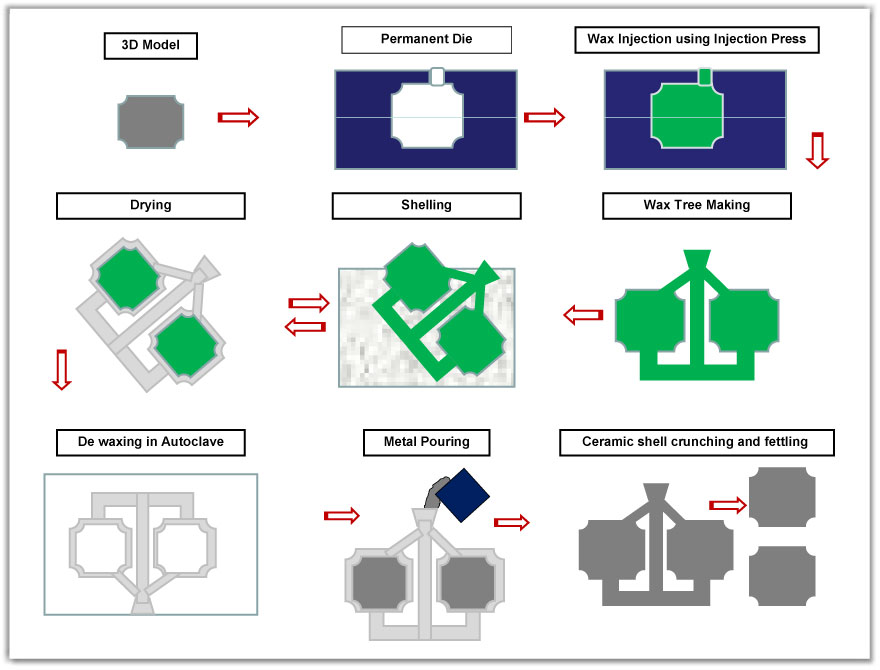

Quick Cast and Cast Form Techniques Casting

Steps involved in Quick Cast and Cast Form Techniques Casting

| Step 1: | Cad data and 2D drawing from Customer |

| Step 2: | Plastic Patterns from SLA or SLS additive layer techniques |

| Step 3: | Construction of tree with plastic pattern and wax gating system |

| Step 4: | Ceramic Shelling process to form ceramic shell over plastic patterns |

| Step 5: | De waxing and ceramic shell burn out |

| Step 6: | Metal Pouring under Vacuum or Open Pouring |

| Step 7: | Ceramic shell breaking , fettling and finishing |

| Step 8: | Heat treatment and sand blasting |

Advantages

- Ideal for 1-3 nos casting

- Good for design Validation

- Short Lead times

- Any Intricate Shape Can be cast

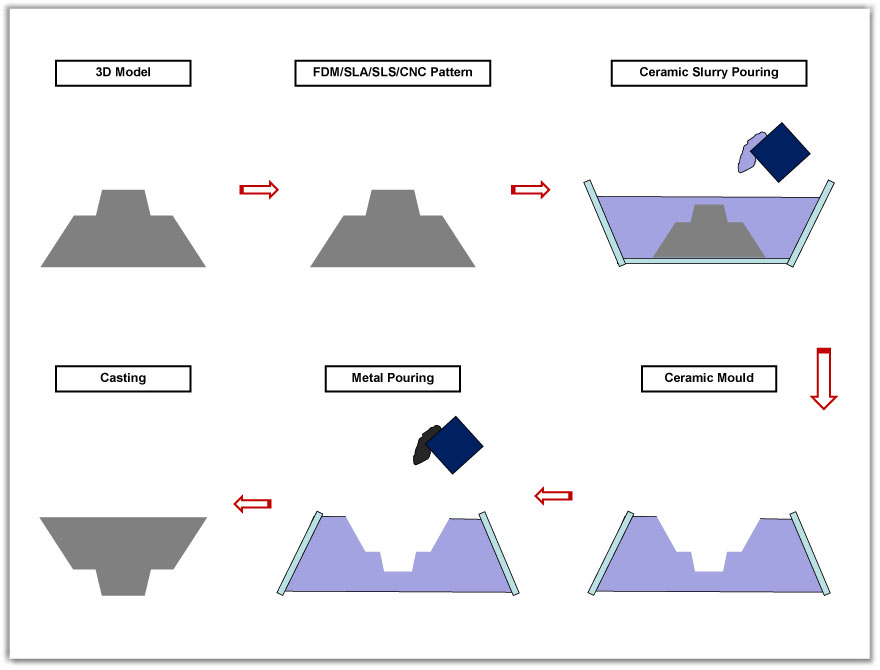

Ceramic Mould Casting

Steps involved in Ceramic Mould Casting

| Step 1: | Cad data and 2D drawing from Customer |

| Step 2: | Plastic Patterns from FDM or CNC machining |

| Step 3: | Mould Making using ceramic |

| Step 4: | Mould Baking |

| Step 5: | Metal Pouring |

| Step 6: | Ceramic shell breaking , fettling and finishing |

| Step 7: | Heat treatment and sand blasting |

Advantages

- Ideal for simple castings

- Comparable to Sand Casting

- Quick Turn around time

- Surface finish better than sand casting